- Home

- Corporate info

- About Roland DG

About Roland DG

In recent years we have been expanding the scope of our business domains and crafting new business models, with a key focus on our two pillars of business: Digital Printing that delivers the potential of on-demand printing across a broad range of fields with our mainline inkjet printers; and DGSHAPE that provides solutions for promoting efficiency of fabrication in various fields by utilizing 3D digital data and for taking advantage of the benefits brought by digitalization at dental laboratories and throughout other healthcare industries.

Going forward, we intend to continue being an innovative company by providing industry and world-first products and solutions, while enhancing the company more valuable by shifting our perspective.

I would be deeply honored to receive your continued support and encouragement.

Kohei Tanabe

President, Representative Director

History

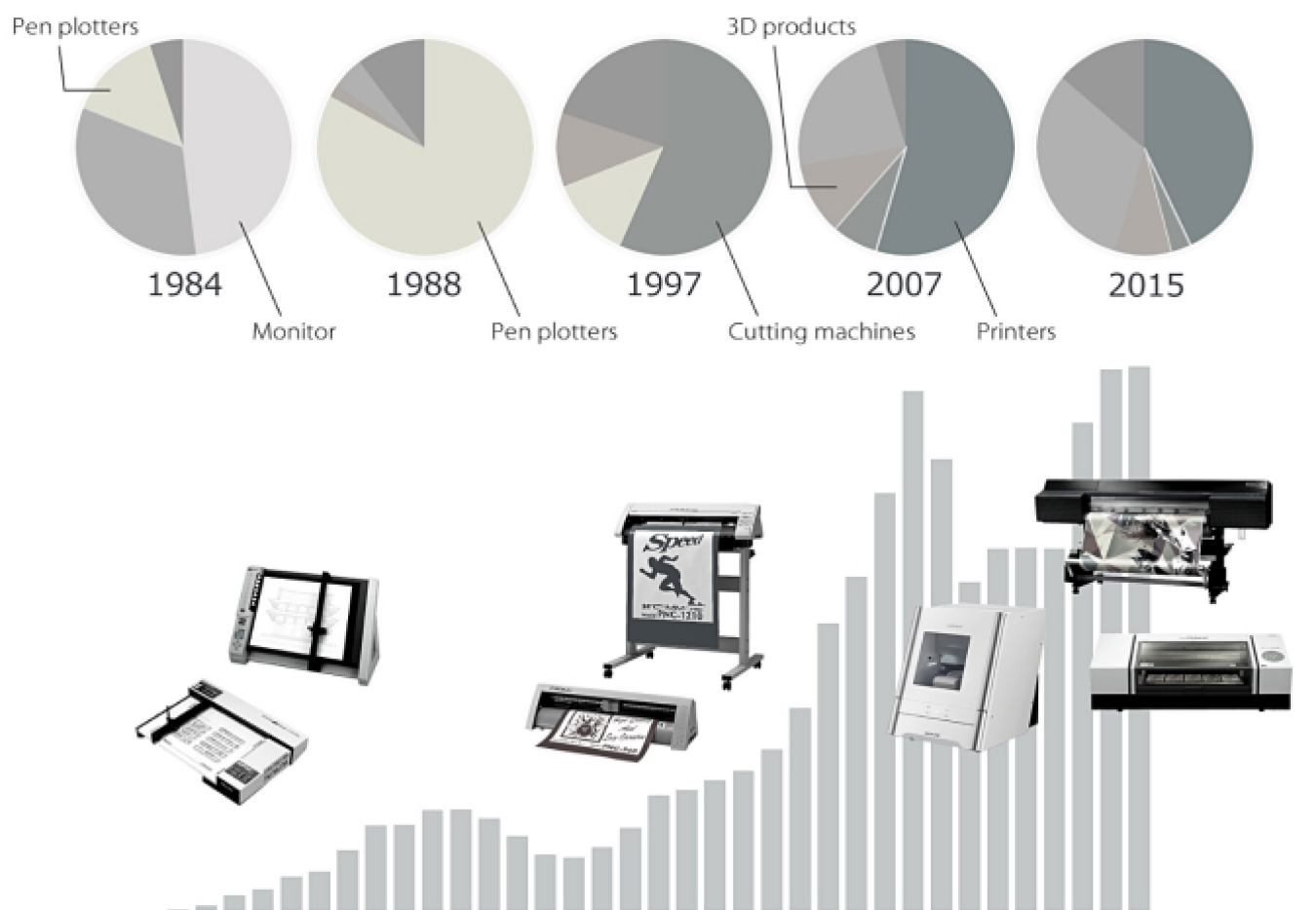

Since the founding of our company, we have pioneered new manufacturing processes based on unique digital technologies that control the XYZ axes or lateral, longitudinal, and vertical movement. Originally applied to the development of pen plotters for designing and drafting applications, our product line soon evolved to include cutting plotters which replaced the pen with a cutter.

Both of these product lines were based on our control technology for the XY axes. The Roland DG line of output devices eventually grew to include color printers equipped with inkjet heads and cutters, and 3D milling machines that controlled the XY and Z axes.

Today, our main line-up of products consists of wide-format inkjet printers that support a variety of industries including the sign industry and machine tools such as milling machines and engraving devices designed to streamline manufacturing processes.

Our core technology

Technology for controlling lateral (X axis), longitudinal (Y axis), and vertical (Z axis) positions.

production system

Roland DG Corporation has production bases in Japan and Thailand. In Japan, it serves as the mother factory, responsible for the production of prototypes, support for the start-up of new product production, and the development of advanced production technologies, while in Thailand, it is responsible for high-quality, stable mass production functions through its unique cell production system "D-Shop," which supports workers with digital technology.